10,000+㎡

Total Factory Area

Total Factory Area

Experience in Curtain Manufacturing

Curtain Designers

New Curtain Designs Provided Monthly

Annual Production Capacity

Experienced Workers

WindowFaces' Nantong factory specializes in the early stages of curtain production, focusing on design and fabric manufacturing, including weaving, dyeing, and printing processes, to transform raw materials into high-quality textiles ready for curtain assembly.

Our weaving machines, meticulously designed, produce fabrics that are tighter and denser compared to others on the market. The high density not only enhances durability but also elevates texture and appearance.

By integrating black yarn during the weaving process, we ensure optimal light blocking capabilities, meeting high customer expectations in both functionality and aesthetics.

At WindowFaces, we are dedicated to sustainability and environmental responsibility. We develop RPET fabrics, made from recycled plastic bottles, to create eco-friendly textile solutions. Our commitment to innovation ensures high-quality products that support a greener future.

We prioritize environmental responsibility by using only eco-friendly dyes that meet international safety standards. Carefully formulated, our dyes ensure quality and consistency in color.

We offer extensive color customization options, allowing customers to choose or blend colors according to their needs. Whether single-color or complex multicolor designs, we meet customer requirements.

Our fabrics achieve a color fastness rating of 3-4, ensuring vibrant and long-lasting colors. Regardless of sunlight exposure or daily use, colors remain unchanged.

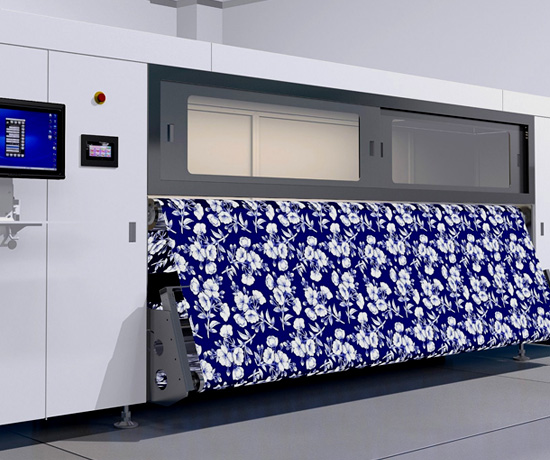

Our traditional printers excel in bulk production, efficiently producing consistent-quality products. This process is suitable for orders requiring large-scale, cost-effective production.

Combining traditional techniques with modern technology, our digital printers realize complex patterns and customized colors. Digital printing is particularly suitable for small-batch production, offering higher flexibility and environmental friendliness.

Digital printing technology is more environmentally friendly compared to traditional printing, reducing water and chemical usage, aligning with our commitment to environmental responsibility.

WindowFaces' Shaoxing factory is a crucial part of the curtain production process, focusing on post-processing and ensuring the quality of the final products. Equipped with advanced equipment and technology, the factory is dedicated to perfecting each curtain.

We use advanced CNC (Computer Numerical Control) cutting equipment and laser cutting machines to ensure the accurate dimensions of each fabric piece. These machines operate at high speeds while maintaining exceptional precision.

Automatic cutting equipment optimizes cutting paths to minimize material waste, thereby reducing production costs.

Ensuring smooth edges of each fabric piece lays a solid foundation for subsequent sewing work.

Equipped with multifunctional computer-controlled sewing machines capable of various types of stitching, including straight, overlock, flat, and decorative stitches.

Automated sewing systems enhance production efficiency, reduce human errors, and ensure precise stitching.

To meet the diverse requirements of different curtain styles, we have specialized sewing equipment such as pleating machines and hemming machines for intricate decorative stitching.

Modern high-temperature ironing machines are used to iron each fabric piece, ensuring curtains are smooth and wrinkle-free.

Shaping machines shape curtains using high temperature and pressure to maintain their form during use.

Professional inspection equipment is used to rigorously inspect the dimensions, shape, and appearance of curtains to ensure each finished product meets high standards.

Our quality control team utilizes fully automated testing equipment to test fabric density, color fastness, and abrasion resistance, ensuring high-quality raw materials.

An online quality monitoring system continuously monitors every aspect of the production process to promptly detect and correct any quality issues.

Testing the fabric's maximum stretch strength, tear resistance, and elongation before breaking. It is essential for assessing the quality and durability of curtains.

We select materials that comply with environmental standards, such as renewable resources and recyclable materials, to reduce our environmental impact.

Introducing advanced clean production technologies, including efficient energy utilization and waste management systems, to minimize waste and emissions during the production process.

Optimizing production processes, employing energy-saving equipment and technologies to minimize energy consumption, and reducing the demand for resources.